IBC Metal Group export 8620 Engineering Steel to all corners of the globe. It is a low nickel, chromium, molybdenum alloy that can be hardened through case hardening (carburizing). This steel usually comes in an as-rolled condition with a maximum brinell hardness of 280 (Rc 30), and when carburized and tempered, it offers good core strength and toughness in medium to small sections with a case hardness up to Rc 62. Additionally, it can also be used (in an uncarburised state) as a high tensile steel which displays good tensile strength and satisfactory toughness when appropriately hardened and tempered for various purposes. To create even harder surfaces, pre-hardened and tempered 8620 can undergo nitriding, but flame or induction hardening will have less than satisfactory results due to its low carbon content.

What Does AISI 8620 Mean?

In the market, we can often see AISI 8620 or SAE8620, in fact, they all refer to 8620 steel, the difference that one named by the American Iron and Steel Institute (AISI) and the other one named by the Society of Automotive Engineers (SAE). They jointly developed and shared a set of steel grade numbering system: Unified Numbering System, referred to as UNS. Here, we can find UNS G86200, it is the number for 8620 steel.

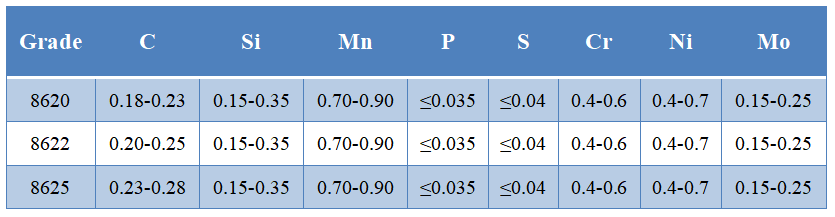

For 8620, The first number ‘8’ indicates that the steel is Nickel Chromium Molybdenum Steel, and 86XX means 0.5%Ni, 0.5%Cr, 0.2%Mo. The last two numbers ‘20’ indicates the amount of carbon present in the steel. For this grade it has 0.20% carbon same as AISI 1020 steel. In 86XX series, besides 8620 steel, 8622 and 8625 also commonly used in the industry, we can see the difference in composition in the following table:

AISI 8620 Engineering Steel Supply Range

- 8620 Round Bar: diameter 8mm – 3000mm

- AISI 8620 Steel Plate: thickness 10mm – 1500mm x width 200mm – 3000mm

- 8620 Square Bar: 20mm – 500mm

- Engineering Steel 8620 tubes are also available against your detailed request.

- Surface Finish: Black, Rough Machined, Turned or as per given requirements.

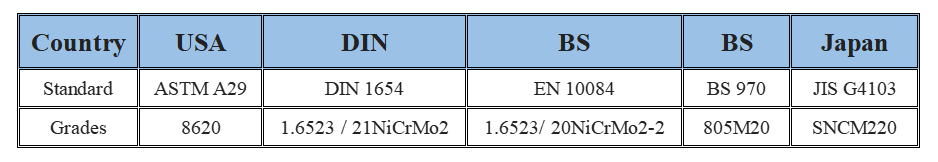

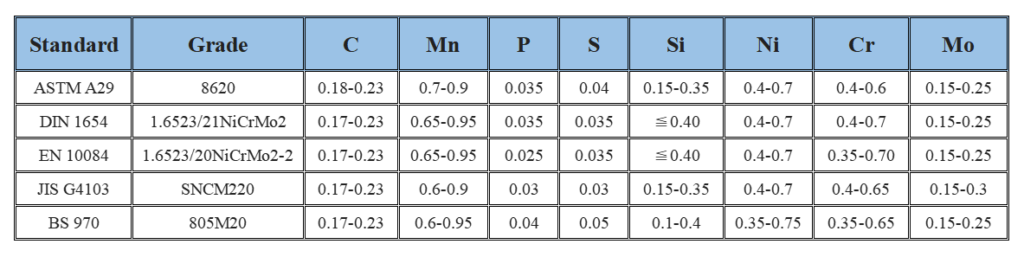

SAE 8620 Steel Specification and Relevant Standards

ASTM 8620 Steels & Equilvalents Chemical Composition

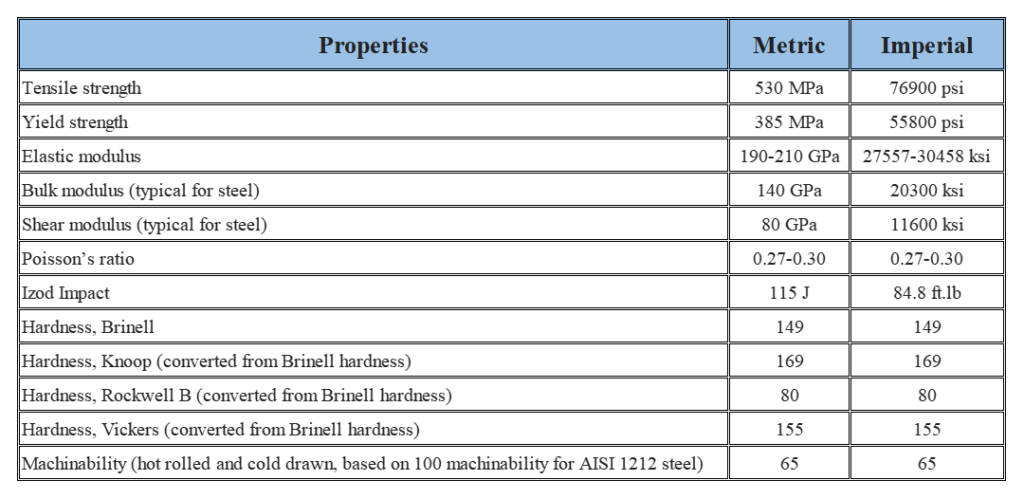

AISI 8620 Steel Mechanical Properties

AISI Engineering Steel 8620 Physical Properties:

- ① Density (lb / cu. in.) 0.283.

- ② Specific Gravity 7.8.

- ③ Specific Heat (Btu/lb/Deg F – [32-212 Deg F]) 0.1;

- ④ Melting Point (Deg F) 2600;

- ⑤ Thermal Conductivity 26;

- ⑥ Mean Coeff Thermal Expansion 6.6;

- ⑦ Modulus of Elasticity Tension 31;

Forging of Material 8620 Steel

AISI 8620 alloy steel forged at a start temperature of around 2250ºF (1230ºC) down to approximately 1700ºF(925ºC.) prior to the hardening heat treatment or carburizing. The alloy is air cooled after forging.

ASTM 8620 Steel Heat Treatment

① Annealing —— Heat AISI 8620 steel to 820°C – 850°C, hold until temperature is uniform throughout the section, then cool in a furnace or by air. ② Tempering —— Heat-treated and water-quenched parts of 8620 steels (not carburized) are tempered at 400F to 1300F to improve case toughness without affecting hardness. ③ Hardening —— The AISI steel 8620 austenitized at around 840°C – 870°C. And oil or water quenched depending upon section size and intricacy. Cool in Air or Oil required. ④ Normalizing —— 1675ºF (910ºC) and air cool. Another method of improving machinability in 8620 material. Normalizing might also be used prior to case hardening.

Machinability of SAE 8620 Steel

The 8620 alloy steel readily machined after heat treatment and/or carburizing. Should be at a minimum so as not to impair the hardened case of the part. Machining may be done by conventional means prior to heat treatment – after carburizing machining is usually limited to grinding.

Welding of 8620 Materials

The alloy 8620 welded as rolled condition by conventional methods, usually gas or arc welding. Preheating at 400 F is beneficial and subsequent heating after welding is recommended – consult the approved weld procedure for the method used. However, welding in the case hardened or through hardened condition not recommended

Application of ASTM 8620 Engineering Steel

Typical applications: Arbors, Bearings, Bushings, Cam Shafts, Differential Pinions; Guide Pins, King Pins, Pistons Pins, Gears, Splined Shafts; Ratchets, Sleeves. And other applications where it is helpful to have a steel that can be readily machined and carburized to controlled case depths.

Conclusion

IBC Metal Group can supply all kinds of special steels. 8620 Engineering Steel, one type of material widely used by all industry sectors. This material is suitable for light to medium-stressed components and shafts that require high surface wear resistance and sufficient core strength and impact resistance. For more information, please contact with us today!

Contact with us today!