In this article, we are going to explore the difference between galvanized pipe and seamless steel pipe. If you’re on the lookout for a reliable pipe option for your upcoming project, you might come across two popular options—galvanized and steel pipes. Though both can be useful in certain scenarios, it’s important to comprehend the differences before making a final call. Let’s compare steel pipe to galvanized pipe so that you can make an informed choice.

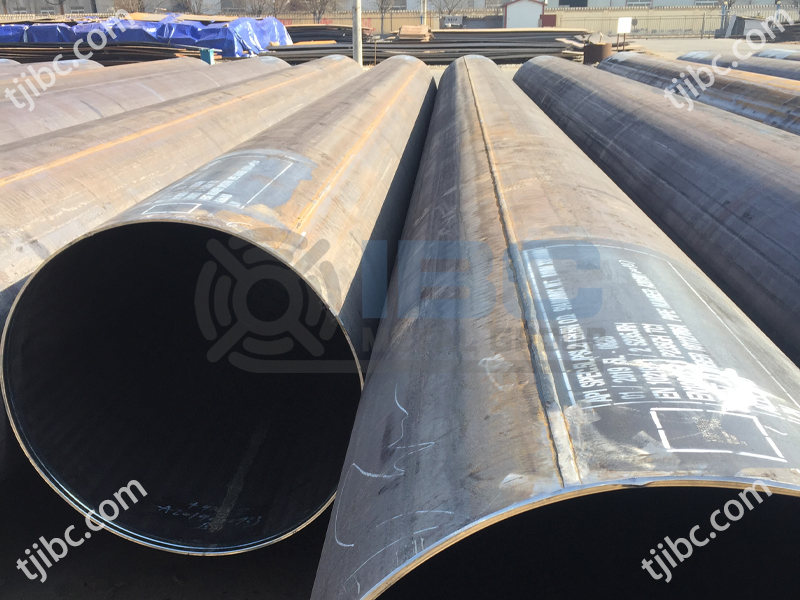

Ordinary Steel Pipes

Ordinary steel pipes are not as resistant to corrosion as galvanized steel pipes. Which have a zinc plating coating over their surface. The two types of steel pipe are either welded or seamless. With the welding type having some connecting points and the latter being manufactured without any joints. Galvanized pipes are hardier against rusting due to the zinc protection. But they are also lightweight, making them ideal for use in railings in balconies. However, seamless pipes, because of their greater wall thickness, can take more pressure and have more weight. Though they may be too expensive for this purpose. With proper care such as welding and painting correctly, galvanized steel pipe can last for over 20 years with no problems. Galvanized Steel is commonly used in fences, guardrails in gardens and residential areas, as well as other places like factories and schools.

Steel Pipes With Galvanized Coating

Galvanized pipes come in two variations: hot-dip galvanizing and cold-galvanizing. The former involves dipping the pipe in a high-temperature zinc liquid, resulting in a thick layer of protection on the surface that is resistant to corrosion. On the other hand, the cold-dip galvanizing method utilizes electroplating to adhere a thin, easily eroded zinc coating onto the tube. It is worth noting that both types of pipes are more expensive than standard steel pipes, though special spraying can drastically improve their anti-corrosive properties.

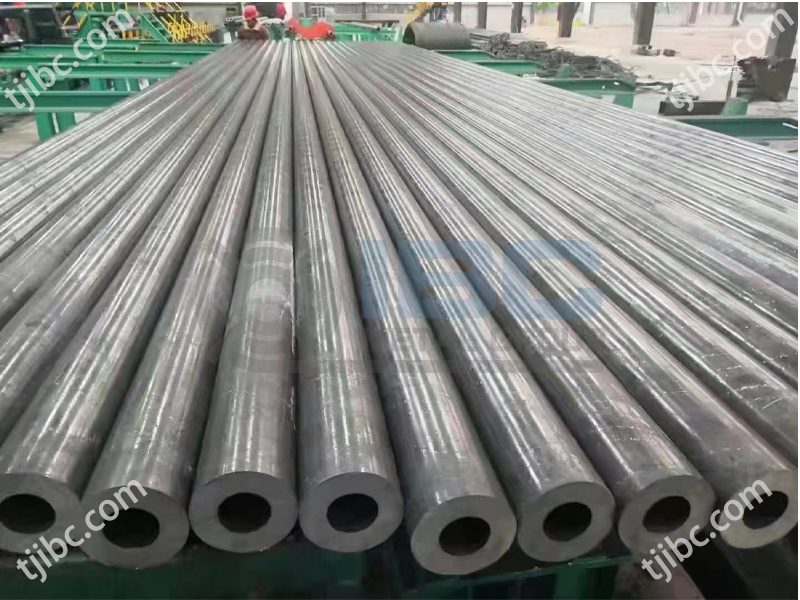

Differences in Manufacturing Process:

Galvanized steel pipe and seamless steel pipe are two kinds of steel pipe. The former is galvanized on the surface, which may be welded or seamless, while the latter refers to its manufacturing process. Galvanized steel pipe is corrosion-resistant and can bear greater pressure than the seamless sort. It is also not prone to rust due to zinc protection. For balconies, it is preferable to use galvanized light pipes as seamless steel pipe is too thick and heavy in weight, besides being costlier. If quality is superb, a galvanized steel pipe should last for more than 20 years with proper welding and painting.

Difference Usage:

Galvanized steel pipes are usually employed to construct fences, balconies and other similar structures, while seamless steel tubes are widely utilized in various municipal engineering projects, industrial facilities and public areas such as roads, factories, schools, parks and residential areas. The latter are also essential commodities for the industry and can be used to transport fluids. When it comes to mechanical components fabrication, seamless steel pipes are the preferred choice due to their ability to withstand moderate load, speed and impact – which makes them popular among petroleum, aviation and automotive industries.

Conclusion:

When it comes to steel or galvanized pipe, the decision should be based on where and how you will use the piping. For outdoor projects in high-moisture areas, galvanized is a better choice due to its increased resistance to corrosion and rusting. But, standard steel may be all you need if your project is not in an area susceptible to moisture and temperature changes. It pays to know the differences between these two types of pipe so you can make an educated decision.

Contact with IBC Metal Group Today!