At IBC (Tianjin) Industrial Co., Ltd, we manufacture the vast majority of 52100 bearing steel, which is the standard material for most domestically manufactured miniature and instrument bearings for aerospace and medical applications. We also provide specially heat treated material for cryogenic applications or other extreme environments and occasionally manufacture ball bearings from other specialty steels.

What is 52100 bearing steel?

ASTM A295 52100 bearing steel is a high carbon, chromium containing low alloy steel that is through hardening and noted in particular for use as bearings. It is one kind of special steel with features of high wear resistance and rolling fatigue strength. High-carbon chromium bearing steel, engineering steel and some types of stainless steel and heat resistant steel used as materials of bearings and for other purposes.

What is Bearing Steel?

Bearing steel, the steel used to make balls, rollers and bearing rings. Bearing steel has high and uniform hardness and wear resistance, as well as a high elastic limit. The requirements for the uniformity of the chemical composition of the bearing steel, the content and distribution of non-metallic inclusions, and the distribution of carbides are very strict, and it is one of the most stringent steel grades in all steel production.

Supply Range of ASTM A295 52100 Steel

AISI 52100 Steel Round Bar: diameter 8mm – 800mm

52100 Steel Plate: thickness 2mm –300mm x width 200mm – 800mm Other sizes of 52100 steel as per customer’s requirements.

Process: Cold drawn, hot rolled, forged etc.

Surface Finish: black, rough machined, turned, polished or as per given requirements.

ASTM A295 specification which covers 52100 high carbon bearing quality steel used in the manufacture of anti-friction bearings. And AISI 52100 steel is the most common steel grade in ASTM A295 standard for high-carbon anti-friction bearing steel.

Advantages of Chrome Bearing Steel 52100:

- Superior hardness, 60-67 on Rockwell hardness scale (Rc) at room temperature

- High carbon chrome alloy steel

- Operates continually at temperatures up to 120°C

- Used to produce precision ball bearings and roller bearings

- Cost-effective

- Long working life

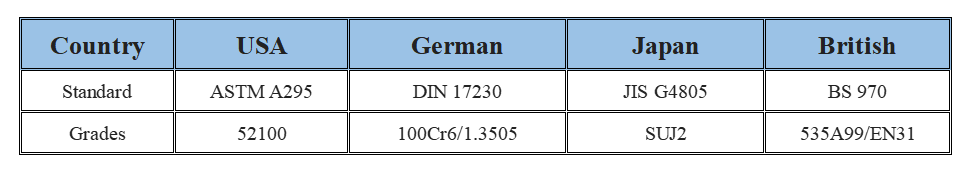

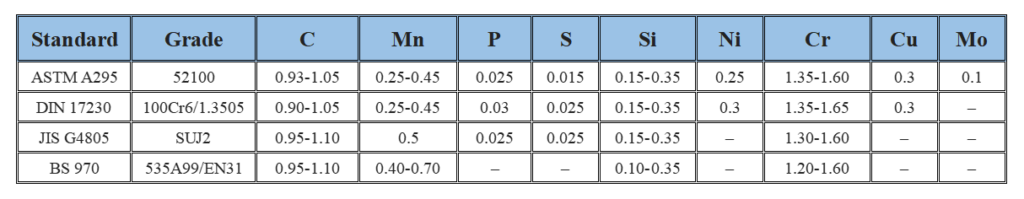

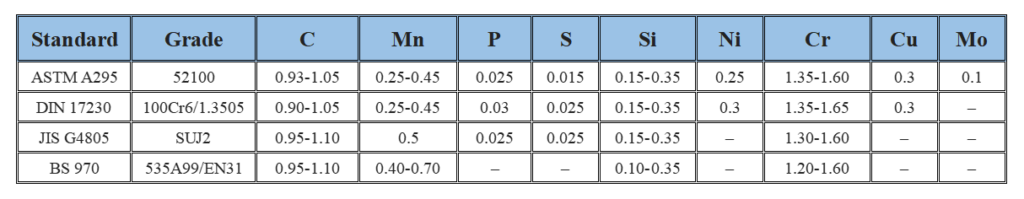

Relevant Steel Specification of ASTM 52100 Bearing Steel

Chemical Composition of 52100 and Equivalents

Mechanical Properties of ASTM A295 52100

Forging of A295 Bearing 52100 Steel

AISI 52100 alloy steel forged at 927 to 1205°C, and should not forge below 925ºC. A post-forge equalization treatment recommended at 745ºC for 4-6 hours followed by air cooling for SAE/AISI 52100 steel.

Heat Treatment for ASTM Bearing Steel 52100

ASTM/AISI 52100 alloy steel heated at 816°C followed by quenching in oil. Before performing this process, it subjected to normalizing heat treatment at 872°C followed by slowly cooling in order to reduce the machining stress.

- Hot Working: AISI 52100 alloy bearing steels can be hot worked at 205 to 538°C.

- Cold Working: AISI 52100 steel can be cold worked using conventional techniques in the annealed or normalized conditions.

- Annealing: For spheroidize anneale, the following isothermal anneal is recommended: 1500ºF (815ºC) for 3 hours; 1350ºF (735ºC) for 4 hours; 1250ºF (675ºC) for 3 hours; Slow cool to 1000ºF (540ºC) then air cool.

- Quenching: AISI 52100 alloy bearing steel could be hardened by quenching in water from 801-829 degree or quench in oil from 816-842 degree.

- Tempering: Temper to desired hardness as indicated by tempering curves after water or oil quench.

Application

52100 alloy steel mainly used for the manufacture of aircraft bearings and other highly stressed parts. This grade 52100 steel preferably vacuum arc re-melted to give optimum performance. Typical applications: Bearing Manufacture, CV joints, ball screws, gauges, knife etc.

Contact with IBC Metal Group Today!