Steel Pipe Dimensions is the method to describe the pipe sizes. IBC (Tianjin) Industrial Co.,Ltd could manufacturer many kinds of steel pipes. From weld seam, it includes seamless or welded steel pipe. From shape of the pipe, it could separate into round pipe, and rectangular pipe. No matter which way to separate them, we need to describe the pipe correctly when we want to place the order. In case of any misunderstandings or a different size we purchased, that would be a big problem. We always get confused about how to describe steel pipe dimensions (sizes) in the correct way.

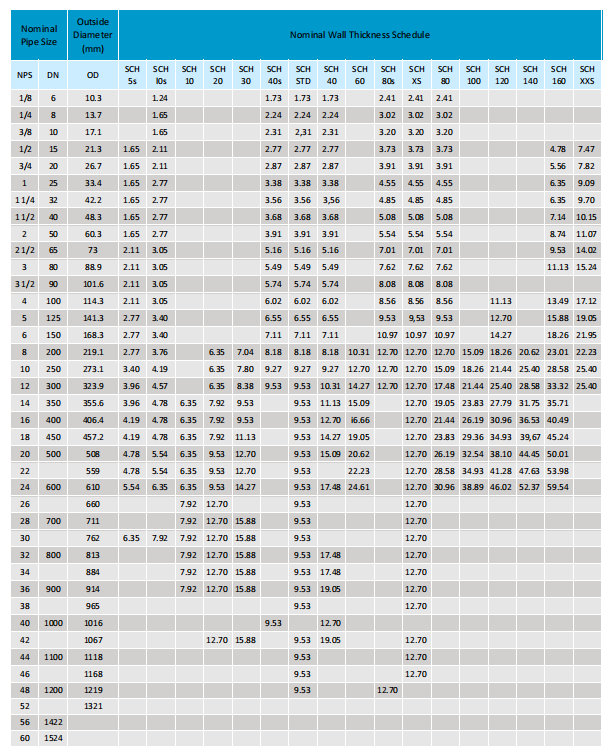

Steel Pipe Dimensions Chart (Size Chart)

A completely description for steel pipe dimension includes outer diameter (OD), wall thickness (WT), pipe length (Normally 20 ft 6 meter, or 40 ft 12 meters). Through these characters we could calculate the pipe weight, how much pressure pipe could bear, and the cost per foot or per meter. Therefore, that’s why we always need to know a right pipe size.

And finally, we will tells you how to describe steel pipe dimensions & sizes correctly. So, what are the exactly right ways to express the steel pipe dimensions? For your better understanding, we will explain from below aspects:

Ways of Express Pipe Dimensions

- For Pipe wall thickness: Use Steel Pipe Schedule, like schedule 40 steel pipe, schedule 80 pipe.

- For pipe Diameters: Nominal Pipe Size (NPS) and DN (Nominal Diameter)

- Pipe weight Class (WGT), LB/FT (Pounds per foot), KG/M (Kg per meter)

What is the Nominal Pipe Size (NPS)?

Nominal Pipe Size (NPS) is a North American set of standard sizes for pipes used for high or low pressures and temperatures. Pipe size is specified with two non-dimensional numbers: a nominal pipe size (NPS) based on inches, and a schedule (Sched. or Sch.).

Characters for a Pipe Dimension

- Dimension Standards of carbon and stainless steel pipe (ASME B36.10M & B36.19M)

- Pipe Size Schedule (Schedule 40 & 80 steel pipe means)

- Means of Nominal Pipe Size (NPS) and Nominal Diameter (DN)

- Steel Pipe Dimension Chart (Size chart)

- Pipe Weight Class Schedule (WGT)

What is DN (Nominal Diameter)?

The nominal diameter of a pipe is typically referred to as the outside diameter, as the wall of the pipe is very thin, so the inside and outside diameters are almost equal. DN (nominal diameter) is used for different types of pipes and their accessories, which have interchangeable parts with the same size. The nominal size is represented by a numerical figure followed by “DN”, and then denoted in millimeters – e.g DN50 stands for a pipe with a nominal diameter of 50 mm. It should be noted that although this value may be close or equal to the inside diameter of pipe, it is not actually the true measurement of its size.

How to Describe Steel Pipe Dimensions and Size Correctly?

For example:

- We could expressed as “pipe outside diameter×wall thickness”, such as Φ 88.9mm x 5.49mm (3 1/2” x 0.216” ). 114.3mm x 6.02mm (4 1/2” x 0.237”), length 6m (20ft) or 12m (40ft), Single Random Length (SRL 18-25ft), or Double Random Length (DRL 38-40ft).

- If Expressed as “NPS x Schedule”, NPS 3 inch x Sch 40, NPS 4 inch x Sch 40. Same size as above specification.

- Expressed as “NPS x WGT Class”, NPS 3 inch x SCH STD, NPS 4 inch x SCH STD. Same size above.

- There is another way, in North America and South America, usually use “Pipe Outer Diameter x lb/ft” to describe pipe size. As OD 3 1/2”, 16.8 lb/ft. lb/ft is pound per feet.

Dimension Standards for Steel Pipe

There are different standards to describe the steel pipe size, OD and wall thickness. Mainly are ASME B 36.10, ASME B 36.19. Relevant standard specification are ASME B 36.10M and B 36.19M. Both ASME B36.10 and B36.19 are the standard specification for the dimensions of the steel pipe and accessories.

ASME B36.10M

The ASME B 36.10M covers standardization of steel pipe dimensions and sizes, which include both seamless and welded types for use in different installations under varying temperatures and pressures. This pipe is specifically designed for pipeline systems transporting fluids such as oil, gas, water or slurry. The pipe dimensions differ from tubes in that the outer diameter of a pipe is always larger than its corresponding nominal size (NPS or Nominal Diameter). Conversely, steel tube sizes are measured by their exact outside diameter ensuring consistency across all sizes.

We need to acknowledge that, when it comes to pipe sizes from NPS 1/8 (DN 6) up to NPS 12 (DN 300), they are based on a standard outside diameter (O.D.). This was determined in order to define the pipe’s dimension, however since pipes always have an inner and outer wall thickness as well as an internal diameter (ID), there is a discrepancy in size between them for smaller pipes. As dimensions increase, the OD and ID begin to approach each other in terms of size.

As there is no such relation between the old standard thickness (O.D.) and Nominal Size, so both of them accepted by standard ASME B 36.10 M. In ASME B36.10M, Pipe schedule identified as Standard (STD), Ex-Standard (XS), or Double Extra Strong(XSS); Or with Schedule No. 5, 10, 20, 30, 40, 80, 120, 160.

ASME B36.19M

ASTM B36.19M is for the stainless steel pipe dimensions, included seamless and welded types as the same. This dimension standard mostly is same with ASTM B36.10M. Wherever the different part is:

- a. For NPS 14 to NPS 22 (DN 350-550), schedule 10S;

- b. NPS 12 of Schedule 40S

- c. NPS 10 and 12 of schedule 80S.

Above mentioned pipe thickness is different with B36.10M, so suffix “S” is used here.

What is Steel Pipe Dimensions Schedule?

A steel pipe schedule, which appears in ASME B 36.10 and is also used in many other standards, is marked with “Sch”. In the American steel pipe standard, Sch stands for schedule, a prefix of a series number. For instance, Sch 80, 80 is a pipe number from ASME B 36.10.

In order to transport fluids under pressure, steel pipes have an internal diameter that is considered their critical size. The nominal bore (NB) is derived from this critical size. In order for steel pipe to carry fluids under pressure, it must have enough strength and thickness in its walls. Accordingly, wall thickness is specified in Schedules, which are the pipe schedules, abbreviated as SCH. Here, ASME is the given standard and definition for pipe schedules.”

The pipe schedule formula:

- Sch.=P/[ó]t×1000

- P is the Designed pressure, units in MPa;

- [ó]t is Allowable stress of materials under design temperature, Units in MPa.

What Does SCH Mean For The Steel Pipe Dimensions

When speaking of steel pipe parameters, the pipe schedule is often evoked. Essentially, this method involves representing pipe wall thickness through numeric values. This schedule is not a single wall thickness, however; instead, it is a series of varying thickness for pipes of the same diameter. Commonly referenced schedules include SCH 5, 5S, 10, 10S, 20, 20S, 30, 40, 40S, 60, 80, 80S, 100, 120, 140 and 160. Generally speaking the higher the number in the table designates thicker walls and thus increased pressure resistance.

Meanings of Schedule 40, 80 Steel Pipe Dimension

Are you new to the pipe industry and wondering why Schedule 40 or 80 steel pipes are so frequently requested? As you have read, these schedules refer to a pipe wall thickness. But why is it so popularly sought after? The reason lies in its ability to withstand heavy pressures; due to this advantage, it is often asked for in large quantities. There are no material restrictions either; Schedule 40 pipes can be made from stainless steel (e.g. ASTM A312 Grade 316L) or carbon steel (such as API 5L, ASTM A53, ASTM A106B, A 179, A252, A333 etc.).

Pipe Weight Class Schedule

WGT class (weight class) is an indication of the pipe wall thickness in early, but still used. It has only three grades, namely STD ( standard ), XS ( extra strong ), and XXS ( double extra strong ).

For the earlier production pipe, each caliber has only one specification, called standard tube (STD). In order to deal with high pressure fluid, the thickening pipe (XS) appeared. XXS ( double extra strong ) pipe appeared to handle the higher pressure fluid. People began to require the use of more economical thin-walled pipe until the emergence of new materials processing technology, then gradually appeared the above pipe number. The corresponding relation between pipe schedule and weight class, refer to ASME B36.10 and ASME B36.19 specification.

Contact with IBC Metal Group Today!